Structural Foam Molding

Need lighter, tougher large parts without the heavyweight hassles? Structural foam molding delivers rock-solid durability.

CPS matches your project with the most experienced structural-foam molder in the U.S., so you stay on schedule, on budget, and ahead of the competition.

What Is Structural Foam Molding?

Structural foam molding, sometimes called low-pressure structural foam injection molding, combines molten thermoplastic with inert nitrogen gas or a chemical blowing agent inside the barrel of the press. The mix is injected at low pressure, and the gas expands to “pack out” the cavity, creating a solid, smooth outer skin around a lightweight, cellular core. This dual-density structure makes parts up to 20% lighter yet boosts stiffness and impact resistance. Because clamp forces stay low, engineers can run large plastic parts on smaller presses and even pair the method with gas-assist to refine surface finish, all while cutting material usage and molding stress.

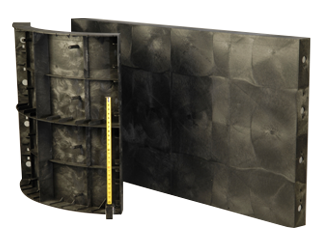

Image courtesy of 20/20 Custom Molded Plastics

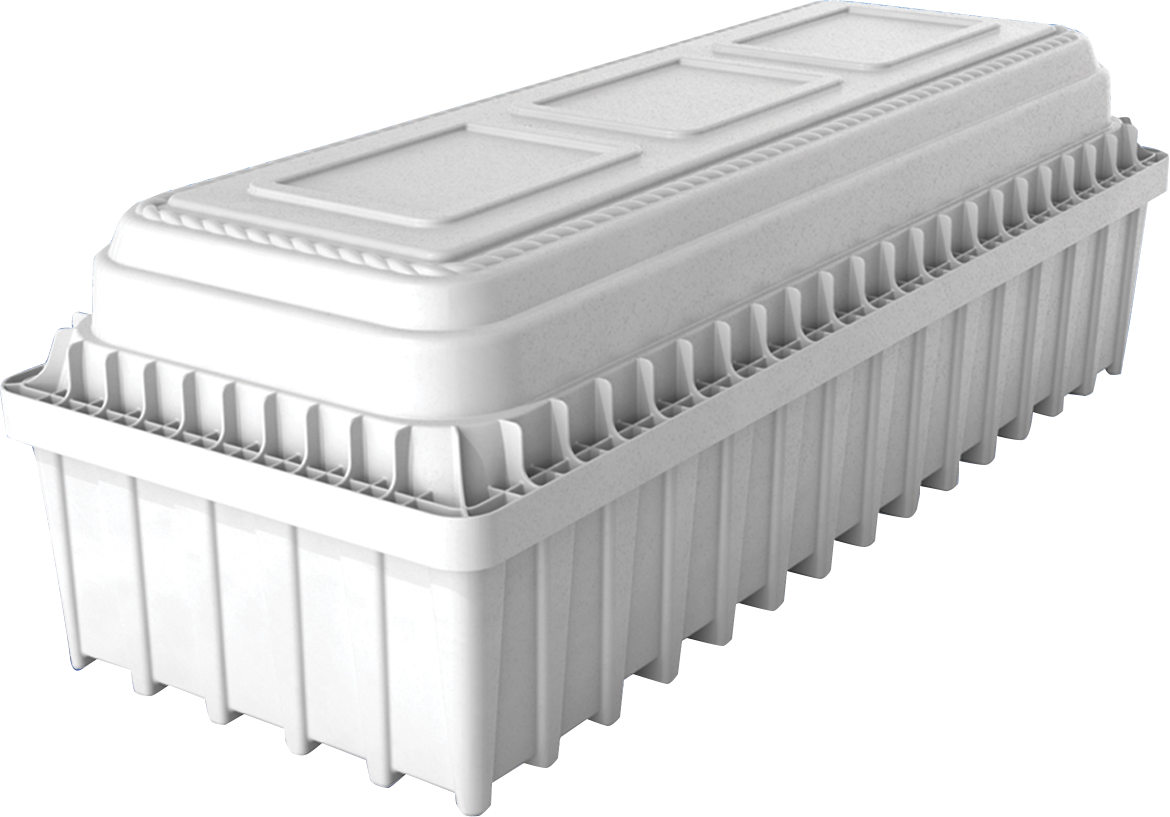

Image courtesy of 20/20 Custom Molded Plastics

Custom Structural Foam Solutions

Need a 10-foot utility cabinet or a pallet that endures warehouse abuse? CPS aligns resin selection, tooling strategy, and production planning with your performance targets, then monitors each milestone so you stay on schedule and on budget. You’ll lower risk and accelerate time-to-revenue.

Why should you choose structural foam molding for your parts?

- Cut weight and resin usage up to 20%

- Mold parts over 10-ft long and 300 lbs. in one shot

- Lower clamp-tonnage means less molded-in stress

- Aluminum tools slash upfront spend and speed iteration

- Minimal sink and warp for consistent, tight-tolerance parts

- Gang-mold multiple parts per cycle for rapid scale-up

- Excellent stiffness-to-weight ratio for demanding part loads

- Recycled resin compatibility supports sustainability goals

Structural Foam Molding Capabilities

Our structural foam molding partner runs more than 40 machines equipped with redundant controls and expansive platens. These presses feature low-pressure, multi-nozzle, and multi-barrel systems that fill thick-section parts evenly. Advanced robotics finish, trim, and assemble parts to your spec. Secondary services such as insert molding, trimming, painting, welding, and kitting mean your parts arrive ready for your line.

Materials Matter

Pick the performance profile you need. Up to 100% recycled content available to hit ESG targets:

- HDPE, LLDPE, PP

Workhorse olefins for pallets, totes, and bins - PS, ABS

Rigid, paint-ready housings and enclosures - Engineering blends

Glass-filled PP, PC/ABS, TPV, urethanes for elevated heat, chemical, or impact demands

Industries We Serve

Construction

Material Handling

Packaging

Water Management

Appliances

Utilities

Industrial Equipment

Transportation

Telecommunications

Powersports

Benefits of Working with Custom Plastic Solutions

You need parts that arrive on time, meet spec, and don’t drag your team through layers of hassle. That’s where we come in. Drawing on nearly 30 years in plastics and focused exclusively on sourcing and process know-how, we match each project with the best resin and manufacturing path, minus the bias you’d expect elsewhere. The result: faster launches, leaner costs, and a smoother supply chain with zero headaches.

Ready to lighten your large parts? Talk with a CPS specialist today and see how structural foam molding can power your next breakthrough.

Frequently Asked Questions

What is structural foam molding and how does it work?

Low pressure structural foam molding is a plastic molding process that uses nitrogen gas and/or chemical blowing agents to create parts with a solid outer shell and a lightweight, cellular core. This results in thick walled, strong, rigid parts that are lighter and use less material than parts made with traditional injection molding.

This type of molding utilizes low-pressure, multi-nozzle machines that include multiple barrels and injection points for each section of the part. Gates are large – about 5/8” in diameter.

Structural foam molding can also be done on standard injection molding machines using single-nozzle injection.

What makes structural foam molding different from injection molding?

Unlike traditional injection molding, structural foam molding uses lower pressure and creates a foamed interior. This reduces weight and material usage, allows larger part sizes, and supports multi-cavity tooling for higher efficiency.

What kinds of parts are best suited for structural foam molding?

Structural foam molding is ideal for large plastic parts that need strength and durability – survivability is more important than lightweighting for most manufacturers. Common applications include pallets, bins, totes, enclosures for electronics and utilities, housings, and structural panels – essentially any large parts that will see harsh environments.

Which plastics can be used in structural foam molding?

Compatible plastics include olefins and styrenics:

- Polyethylene (PE)

- High-density polyethylene (HDPE)

- Polypropylene (PP)

- Polystyrene (PS)

- Acrylonitrile butadiene styrene (ABS)

Some filled engineering-grade resins, including flexible materials such as TPVs and urethanes, can also be used for high-performance applications.

Can structural foam molding handle complex part designs?

Yes. Similar to standard injection molding, structural foam molding supports deep draws, thick walls, and intricate geometries, making it suitable for custom designs in industrial and OEM applications.

How large can structural foam molded parts be?

With the right tooling, parts can be over 10 feet long and weigh up to 300 pounds. This makes the process well-suited for oversized or structural components.

What are the benefits of structural foam molding for large plastic parts?

Structural foam molding offers:

- Reduced manufacturing cost vs. standard injection molding

- Reduced material and part weight

- Consistent part quality shot-to-shot

- Design freedom

- Lower tooling costs (aluminum vs. steel)

- High stiffness and strength

- Minimal warping or shrinkage

- Efficient multi-part molding

How does structural foam molding reduce manufacturing costs?

You can make a large part in a smaller tonnage machine than with standard injection molding. In addition, by utilizing gang tooling, multiple parts can be made per machine cycle, so the energy usage and operational cost is lower. It also reduces material usage and discreet cycle times. Low-pressure requirements and multi-cavity tooling further drive down production and tooling costs.

Which industries use structural foam molded parts?

Industries that benefit from structural foam molding include:

- Construction

- Material handling

- Packaging

- Water Management

- Consumer goods

- Appliances

- Utilities

- Industrial equipment

- Recreational products / Powersports

- Transportation

- Telecommunications

Is structural foam molding environmentally friendly?

Yes. It produces less material waste and creates lighter parts, which reduce transportation emissions and energy use. Many parts are made with 100% recycled materials. It’s a more sustainable option compared to traditional injection molding.

What are the lead times for a structural foam molding project?

Lead times vary widely by the project, part complexity, and tooling lead times – from 4 to 20 weeks generally. We will work with you to determine realistic, project-based delivery timelines so that you can plan accordingly.

How does Custom Plastic Solutions ensure quality in foam molded parts?

We work with proven partners like 20/20 Custom Molded Plastics to ensure precision, consistency, and industry-grade performance in every molded part. They mold in the U.S., are the most experienced low-pressure structural foam molding firm in the world. They feature all new equipment, over 40 machines with redundant controls for ease of operation, tool handling expertise, and ISO certification.

How can I request a quote or get started with a project?

Visit our contact us page or give us a call at 440-539-2433 to discuss your part requirements. We'll guide you through the process and connect you with the right manufacturing partner. If we can’t help you, we’ll connect you with someone who can.

Our Processing Partner