Compression Molding

For heavy-duty plastic parts that stand up to impact, vibration, and the elements, compression molding delivers high strength, dimensional stability over a wide temperature range, and consistent performance at scale.

We provide you with compression molding services for rugged, load-bearing parts made with precision-formulated compounds and recycled content.

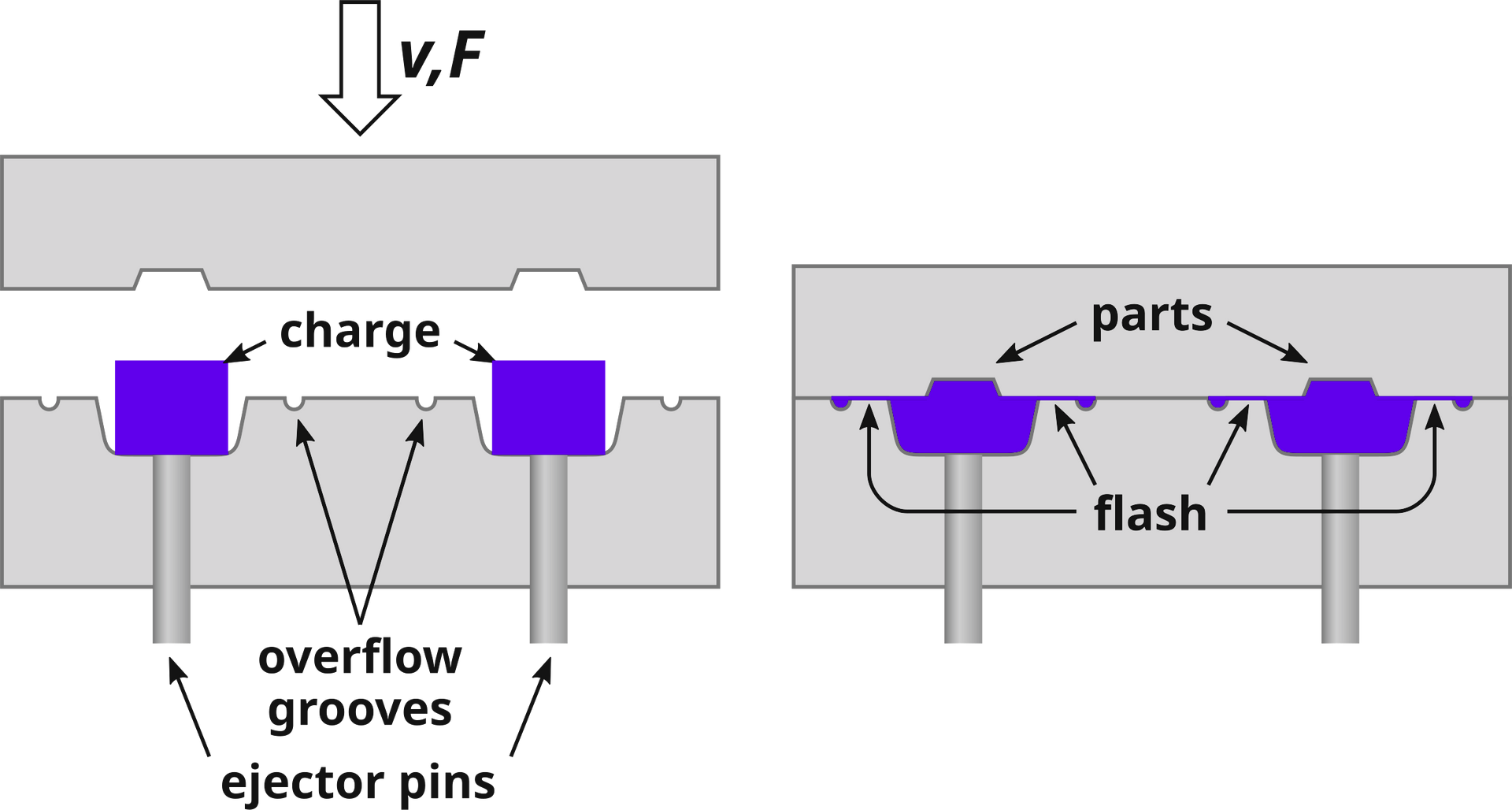

What Is Compression Molding?

Compression molding is a closed-mold process where a measured amount of material - often a bulk molding compound (BMC) or sheet molding compound (SMC) - is placed into a heated mold cavity. The mold is then closed, and pressure is applied to shape and cure the part. Unlike injection molding, this process doesn’t require sprues or runners and operates at lower pressures, making it ideal for molding thick-walled, high-strength structural components with uniform density and minimal waste. The result is durable plastic parts built to perform in tough environments.

Image credit: ariel cornejo CC BY-SA 4.0 via Wikimedia Commons

Image courtesy of CTC Plastics

Custom Compression Molding Solutions

Need a structural panel made with post-industrial resin or a pallet that can withstand repeated forklift abuse? CPS works with you and our compression molding partner to deliver on strength, sustainability, and consistency. Our partner operates compression presses up to 4000 tons and maintains in-house compounding and formulation control. That means your recycled content, resin blend, and part performance aren’t left to guesswork. We help you launch faster with reliable tooling guidance, lab-tested formulations, and proven press capacity for your volume targets.

Why should you choose compression molding for your parts?

- Produces strong, thick-walled parts with uniform mechanical properties

- Handles virgin, filled, and high-recycled-content materials

- Requires less energy and simpler tooling than injection molding

- Maintains tight tolerances and consistent wall thickness

- Offers smooth surface finishes with minimal secondary processing

- Supports large parts ranging from a few pounds to over 100 pounds

- Reduces waste with highly repeatable cycle control and no runners

- Ideal for structural, load-bearing, or high-impact applications

Compression Molding Capabilities

With presses ranging from 800 to 4000 tons, our molding partner can support both thermoset and thermoplastic programs with in-house tooling management, mold maintenance, and compound testing. Their on-site lab evaluates material blends, including recycled content, to optimize processability and part performance. With extensive experience in tooling transfers and high-volume runs, we are able to streamline your project from start to scale without disruptions or handoffs.

Materials Matter

Our compression molding programs use both virgin and recycled materials, tailored to your mechanical and environmental needs. Each formulation is tested in-house to ensure performance and process consistency:

- PP, PE, and Polyolefin Blends:

Reliable base resins for structural parts, pallets, and industrial housings - Reinforced Compounds:

Mineral, wood flour, and glass-filled grades for added stiffness and durability - High-Recycled-Content Formulations:

Many parts incorporate up to 100% recycled plastic, balancing performance and ESG goals

Image courtesy of CTC Plastics

Industries We Serve

Material Handling

Automotive and Heavy Equipment

Utilities

Telecommunications

Construction

Logistics and Warehousing

Transportation

Agriculture

Appliance and Electrical Enclosures

Image courtesy of CTC Plastics

Benefits of Working with Custom Plastic Solutions

CPS helps you get the most out of compression molding—without the friction of finding the right materials, tooling, or production partner on your own. Our exclusive alignment with a leading U.S.-based compression molder means your project benefits from tested formulations, responsive engineering support, and scalable capacity. Whether you need a pallet, panel, or protective housing, we’ll help you mold it stronger, faster, and more sustainably

Ready to compress cycle times and reduce cost per part? Talk with a CPS specialist today.

Frequently Asked Questions

What types of plastic materials are used in compression molding?

Compression molding is compatible with a wide range of thermosets and thermoplastics, including both virgin and recycled materials. Commonly used resins include polypropylene (PP), polyethylene (PE), and other polyolefins, often reinforced with fillers like glass fiber, mineral, or wood flour. The process is also suitable for engineered compounds designed for high strength, durability, or environmental resistance.

What types of parts are best suited for compression molding?

Compression molding is ideal for heavy-duty plastic parts that need to withstand impact, vibration, or static loads. Common parts include pallets, industrial bases, panels, utility enclosures, and structural components for transportation and material handling.

How is compression molding different from injection or thermoforming?

Unlike injection molding, compression molding uses lower pressures and doesn't require material to flow through sprues and runners. Compared to thermoforming, compression molding allows for thicker walls and better mechanical properties. It’s a good choice for parts that require strength, durability, and the use of high-recycled-content materials.

Can recycled plastic be used in compression molding?

Yes. Compression molding is especially well-suited for recycled materials. CTC Plastics blends and tests recycled content in-house to ensure consistent quality and part performance. Many molded parts contain up to 100% recycled plastic, supporting sustainability goals.

What are the size and weight limits of compression molded parts?

Compression molding supports the production of large, thick-walled parts with significant weight — from just a few pounds to well over 100 pounds, depending on the part design and material. It’s ideal for oversized or heavy-duty components that require strength, impact resistance, and structural integrity without metal reinforcement.

What are the benefits of compression molding?

Key advantages include:

- High strength and stiffness

- Excellent surface finishes with minimal secondary processing

- Efficient processing of recycled materials

- Cost-effective tooling

- Uniform wall thickness and low scrap rates

How does compression molding help reduce costs?

Its main cost reduction benefits come from lower energy consumption, longer tool life, and consistent quality. Tooling is simpler and more affordable than injection molding, and the ability to use recycled materials further reduces material costs. The process also generates less waste and is highly repeatable for high-volume runs of structural parts.

Which industries use compression molded plastic parts?

Industries that benefit from compression molded parts include:

- Material handling and logistics

- Automotive and heavy equipment

- Consumer and commercial appliances

- Telecommunications and electrical infrastructure

- Pallet and transport systems

- Construction and building materials

- Sports and recreation

- Agricultural and farming

- Transportation

How can I request a quote or get started with a compression molding project?

Visit our contact us page or call us at 440-539-2433 to discuss your part requirements. We’ll evaluate your needs for compression molding using high-performance recycled materials.

Our Processing Partner