Gas Assist Molding

Looking for stronger, sleeker parts with less weight and waste? Gas assist molding enhances injection-molded performance from the inside out.

We provide you with skilled gas assist molding production, so your parts look better, perform better, and launch faster with fewer hassles.

What Is Gas Assist Molding?

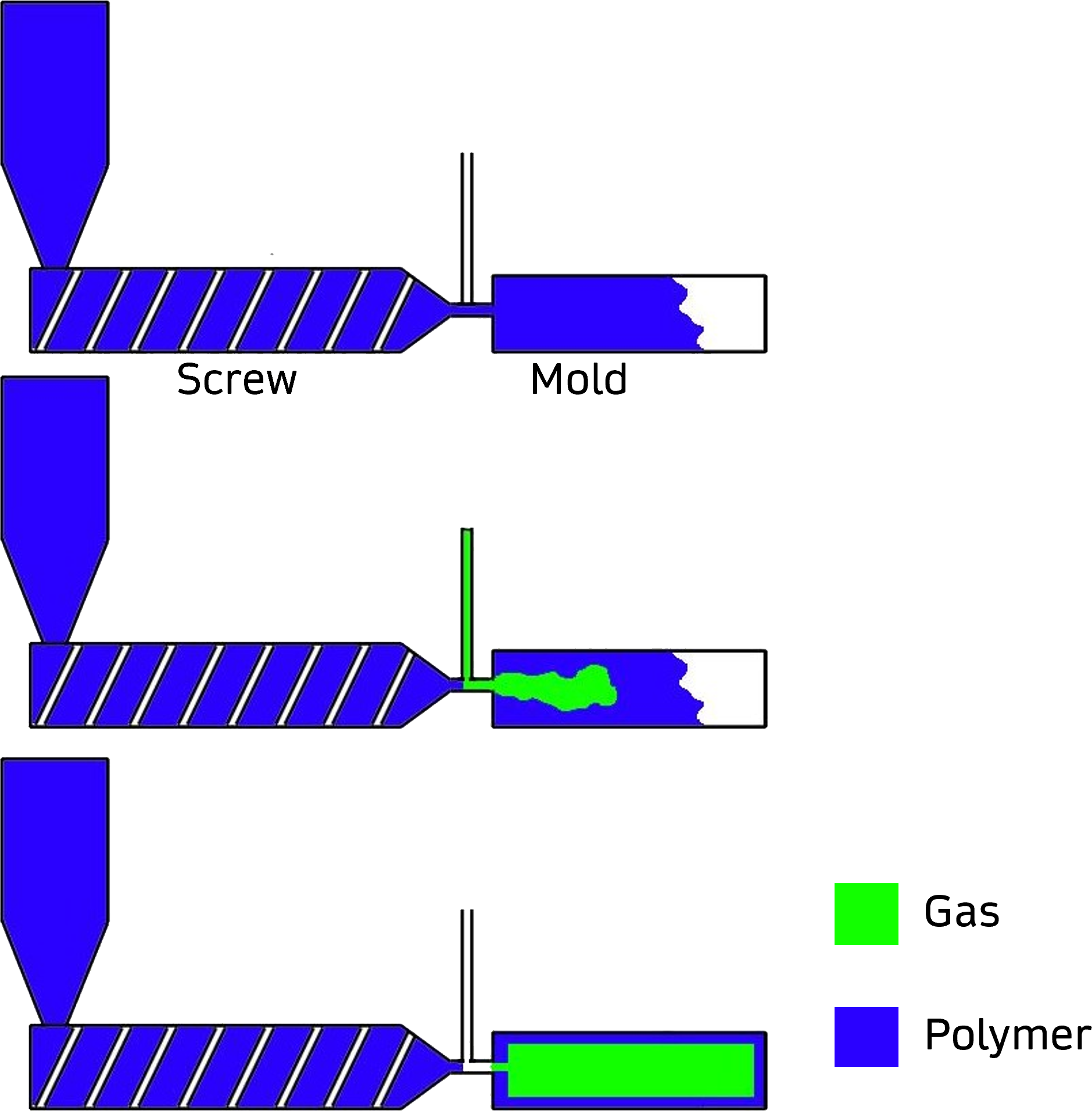

Gas assist molding (also known as Structural Web molding) builds on the standard injection process by introducing pressurized gas (typically nitrogen) into the molten plastic once it’s inside the mold. The gas carves out internal hollow channels, pushing resin to the outer walls. This creates structurally sound parts with complex geometries. Their smooth exterior is bolstered by a hollow core that increases stiffness, reduces material use, and minimizes cosmetic defects. The result? Lighter parts with improved aesthetics and faster cycle times.

Image credit: Esquema_Moldeo_por_inyeccion_asistida_por_gas.jpg: PCarballeda derivative work: Suvroc, CC0, via Wikimedia Commons

Custom Gas Assist Solutions

From grab handles that won’t warp to a molded panel that stays true to spec, CPS meets your part needs. We help you determine whether gas assist is the right fit based on part geometry, material selection, and finish requirements. From concept to cycle optimization, we bring the technical guidance and logistics to make your next project a success.

Why should you choose gas assist molding for your parts?

- Cuts part weight while preserving strength

- Reduces sink, warp, and surface defects

- Improves structural performance with gas-formed ribs

- Shortens cycle times for faster output

- Enables thinner walls and complex geometries

- Lowers material usage and unit cost

- Minimizes post-mold finishing or painting

Gas Assist Molding Capabilities

Our partners use gas-assist capable presses equipped with multi-stage injection and precision gas control. Systems are optimized for thick or complex parts, where consistent wall formation and aesthetic surfaces matter. Value-added services like trimming, secondary operations, and automated assembly can be integrated to simplify your workflow.

Materials Matter

Resins that retain melt strength work best. We’ll guide you to the right fit from standard to engineered grades:

- PP, PE, ABS

Versatile choices for structural and aesthetic parts - PA6, PA66

High-strength options for automotive and load-bearing applications - Materials with high melt strength

Essential for optimal gas channel formation and uniform flow

Industries We Serve

Industrial Equipment

Furniture

Consumer Goods

Powersports

Appliances

Telecom

Utilities

Transportation

Benefits of Working with Custom Plastic Solutions

CPS eliminates the guesswork. We help you decide if gas assist molding is the right process—or steer you to a better fit. With decades of experience in plastics and a nationwide network of qualified partners, we help OEMs cut weight, improve performance, and stay on schedule.

Need help determining if gas assist is right for your part? Talk with a CPS specialist today and get clarity before you decide.

Frequently Asked Questions

What are the benefits of gas assist injection molding?

This process offers several advantages, including:

- Weight Reduction: Hollow sections decrease part weight without compromising strength.

- Greater Stiffness: Gas channels can create an internal rib, which can be used to improve the structural performance of the part.

- Improved Aesthetics: Enhanced surface finishes with minimized sink marks and warpage.

- Material Efficiency: Reduced material usage leads to cost savings.

- Design Flexibility: Enables the creation of complex shapes and thinner walls.

- Shorter Cycle Times: Faster cooling and reduced production times.

Which materials are suitable for gas assist injection molding?

Most thermoplastics compatible with traditional injection molding can be used, including:

- Polypropylene (PP)

- Nylon (PA6, PA66)

- Polyethylene (PE)

- Acrylonitrile Butadiene Styrene (ABS)

Materials with higher melt strength are particularly suitable.

How does gas assist molding compare to traditional injection molding?

Gas assist molding differs by introducing pressurized gas to create hollow sections, resulting in:

- Lighter parts with maintained structural integrity.

- Enhanced surface quality with reduced defects.

- Lower material consumption and production costs.

Traditional injection molding lacks these specific advantages

What types of products are ideal for gas assist injection molding?

This process is well-suited for:

- Large panels and enclosures

- Handles and grab bars

- Automotive components

- Furniture parts

- Consumer electronics housing

- Utility enclosures

- Motor housings

- UTV hoods

- Golf cart roofs and handles

Products requiring complex shapes, reduced weight, and high-quality finishes benefit most.

Is gas assist injection molding cost-effective?

Yes, it reduces material usage and cycle times, leading to lower production costs. The ability to produce complex parts in a single process also can reduce scrap in aesthetic applications.

How does gas assist molding improve part aesthetics?

The pressurized gas minimizes common defects like sink marks and warpage by pressing material to the tool wall. This results in smoother surfaces and more consistent finishes, reducing or eliminating the need for secondary operations such as painting.

Can gas assist injection molding be used for structural components?

Absolutely. The process enhances structural integrity by creating hollow, rib-like features that increase strength while reducing weight, making it suitable for load-bearing applications.

What are the design considerations for gas assist injection molding?

Key considerations include:

- Strategic placement of gas channels to control flow.

- Uniform wall thickness to prevent defects.

- Avoiding complex geometries that may trap gas.

Collaborating with experienced designers ensures these considerations are met.

How can I determine if gas assist injection molding is right for my project?

How can I determine if gas assist injection molding is right for my project? Consulting with Custom Plastic Solutions is the first step. We can help assess your design and production requirements to determine if this process aligns with your goals. Visit our contact us page or call us at 440-539-2433.