Injection Molding

Are you looking for complex, high-volume plastic parts that meet challenging specs? Injection molding delivers unmatched precision and efficiency.

CPS connects you with proven injection molding experts across the U.S., so you can move fast, meet specs, and reduce production risk.

What Is Injection Molding?

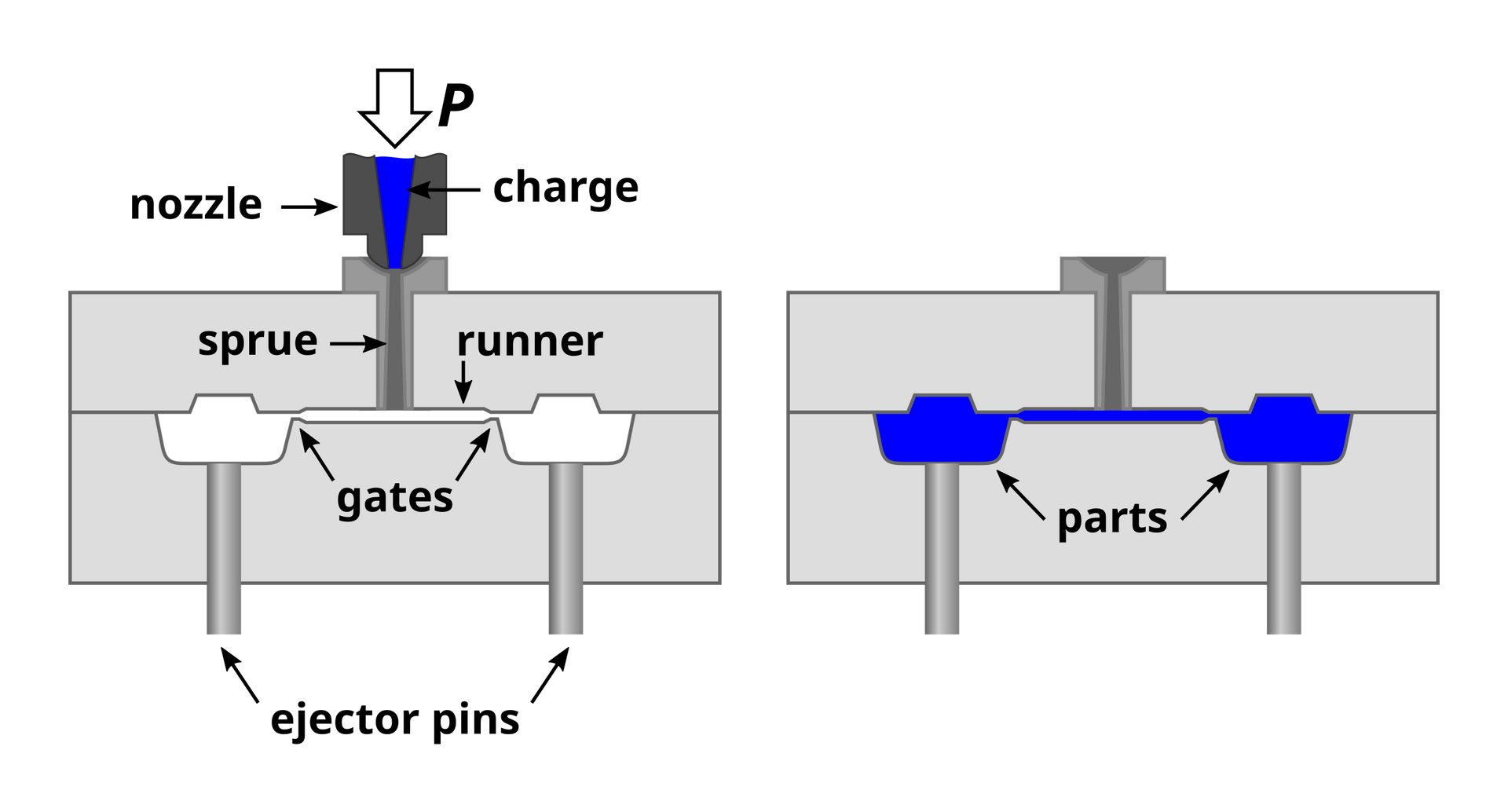

Injection molding is a high-pressure process that melts thermoplastic resin and injects it via a nozzle and sprue into a precision-machined mold. Once the part cools and solidifies, the mold opens and the part is ejected. Then, the cycle begins again, often in mere seconds. This method produces highly repeatable parts with tight tolerances and intricate features. It’s ideal for high-volume production of detailed components across industries, with material and finish flexibility that supports even the most demanding part requirements.

Image credit: ariel cornejo CC BY-SA 4.0 via Wikimedia Commons

Custom Injection Solutions

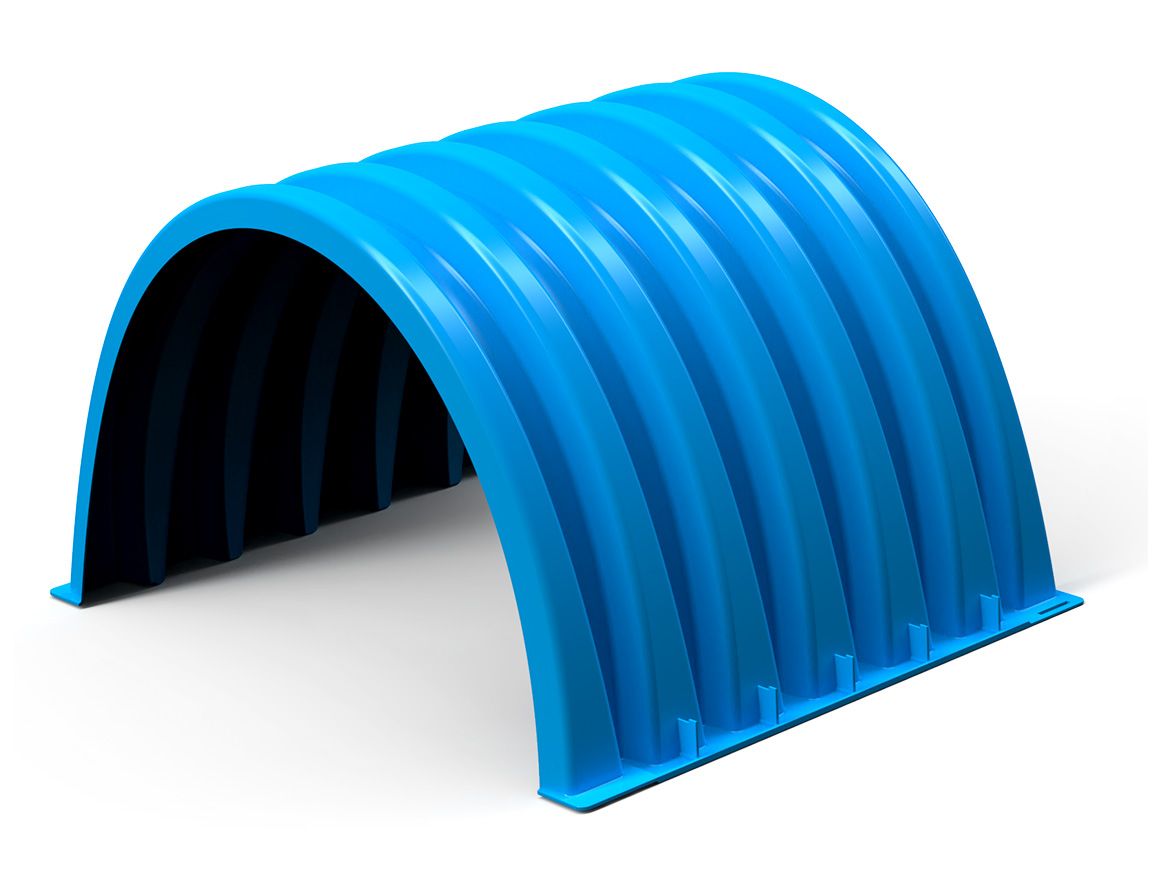

Need a glass-filled nylon connector, a consumer housing with molded-in threads and logos, or a utility enclosure? CPS aligns mold design, material selection, and process planning to hit your targets from the first shot. Whether you're scaling up or retooling a legacy part, we help you control cost, ensure quality, and speed time to market.

Why should you choose injection molding for your parts?

- Supports detailed designs with tight tolerances

- Enables high-speed, high-volume production

- Offers excellent strength with engineering-grade resins

- Delivers smooth finishes and custom branding

- Accommodates a wide range of materials and colors

- Supports complex features like undercuts, threads, and inserts

- Scales cost-effectively from thousands to millions of parts

- Backed by automated quality controls and ISO-certified facilities

Materials Matter

Match the resin to your environment. Whether you need low-cost polyolefins or high-heat polymers for demanding conditions, we’ve got you covered:

PP, PE, ABS

Everyday resins for consumer goods, caps, and general-use parts

PA6, PA66, PC

Engineering polymers for strength, clarity, or dimensional stability

TPEs, TPU, TPV

Flexible materials for seals, grips, and soft-touch applications

PEEK, PPS

High-performance materials for aerospace, medical, and telecommunications

Industries We Serve

Consumer Goods

Medical Devices

Industrial Equipment

Electronics

Packaging

Telecom

Appliances

Transportation

Aerospace

Benefits of Working with Custom Plastic Solutions

You don’t have time for delays, do-overs, or sourcing guesswork. That’s why we focus exclusively on matching the right resin, tooling, and manufacturing partner to your project goals. With over three decades in plastics, CPS delivers smart sourcing, real answers, and dependable results—so you can launch faster and scale with confidence.

Injection Molding Capabilities

Our injection molding partners operate presses ranging from 75 to 8,000 tons, equipped for both conventional and advanced molding techniques. Capabilities include side-action cores, overmolding, insert molding, and multi-shot tooling. Post-mold services such as ultrasonic welding, pad printing, and automated assembly support your downstream efficiency.

Ready to move from CAD to consistent parts? Talk with a CPS specialist today and learn how injection molding can drive your next success.

Frequently Asked Questions

What are the advantages of custom injection molding?

Custom injection molding offers:

- High production efficiency and repeatability

- Tight tolerances for complex part geometries

- Broad material compatibility

- Cost-effectiveness in medium to high production volumes

- Enhanced surface finishes and branding options

What products are made from injection molding?

Injection molding is used to manufacture a wide range of products, including:

- Medical devices (syringes, cases, enclosures)

- Consumer goods (toys, packaging, appliance parts)

- Industrial equipment components and tool housings

- Transportation components (dashboards, housings, bumpers)

Are injection molded parts strong?

Yes, injection molded parts can be very strong, depending on the resin used and part design. Engineering-grade plastics like nylon, polycarbonate, or glass-filled polymers offer excellent mechanical strength, impact resistance, and dimensional stability.

What materials are commonly used in custom injection molding?

Common materials include:

- Polypropylene (PP)

- Polyethylene (PE)

- Acrylonitrile Butadiene Styrene (ABS)

- Nylon (PA6, PA66)

- Polycarbonate (PC)

- Thermoplastic elastomers (TPEs)

- High-performance polymers like PEEK or PPS (for the most demanding applications)

How does the injection molding process work?

The injection molding process includes four main steps:

- Clamping: Mold halves are closed and secured

- Injection: Molten plastic is injected into the mold cavity

- Cooling: The material solidifies into shape

- Ejection: The molded part is released from the mold

This cycle repeats quickly, allowing for high-speed, high-volume production.

What factors influence the cost of custom injection molding?

- Mold design and tooling material

- Resin selection and additives

- Part size and geometry

- Volume of production

- Finishing or assembly requirements

Optimizing material usage and mold design can significantly reduce total cost.

How long does it take to produce injection molded parts?

Typical lead time includes:

- Mold fabrication: 4–12 weeks, depending on complexity

- Part production: Seconds to minutes per cycle, allowing rapid output once tooling is complete. Custom projects with existing molds can begin production quickly.

What quality controls are used in injection molding?

Quality assurance steps ensure consistency, reliability, and minimal defect rates. These include:

- Material verification

- Real-time process monitoring

- Dimensional and visual inspections

- Adherence to ISO or customer-specific standards

Can injection molding handle complex part designs?

Absolutely. Custom injection molding supports tight tolerances, undercuts, threads, and other detailed features. Mold inserts, side actions, and advanced gating techniques allow for highly complex parts.

How long does an injection mold last?

Mold lifespan depends on:

- Material: Steel molds outlast aluminum

- Maintenance: Regular cleaning and upkeep extend usability

- Volume: High-volume molds are designed to withstand hundreds of thousands or even millions of cycles

How do I start a custom injection molding project with Custom Plastic Solutions?

To get started, visit our contact us page or give us a call at 440-539-2433 to discuss your part requirements. Our team will guide you from concept to production with responsive support at every step, and connect you with the right manufacturing partner. If we can’t help you, we’ll connect you with someone who can.